When developing a product, you typically have several manufacturing options from rapid prototyping to injection or rotational molding and more, but productiong molding excels at:

The highly reliable quality from production molding makes it well suited for industries with high-standards.

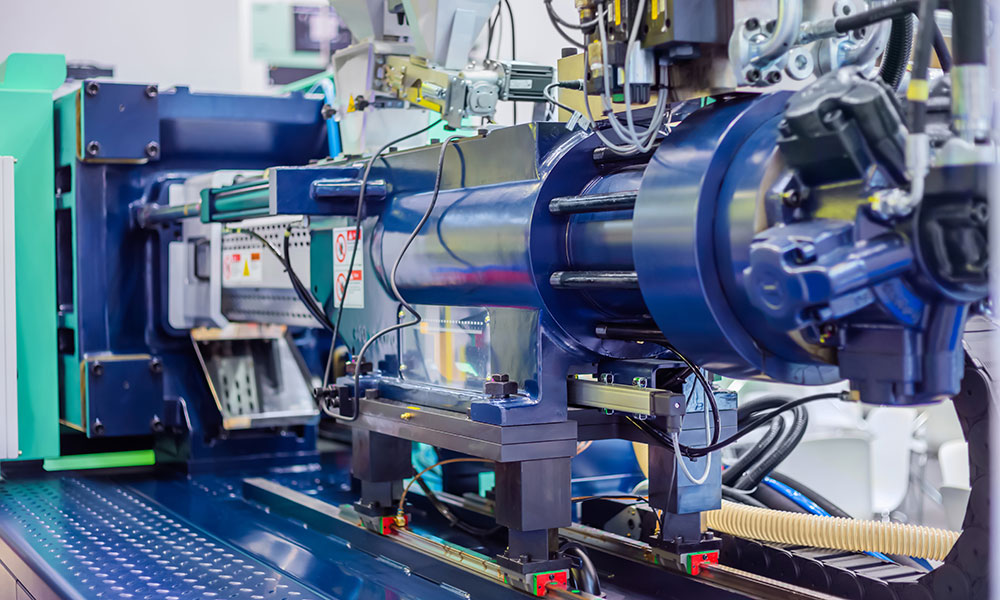

When you work with Blue Water Molding, you get the benefits of our outstanding and innovative molding operations: